Understanding Cutting Equipment: Basics and Variations

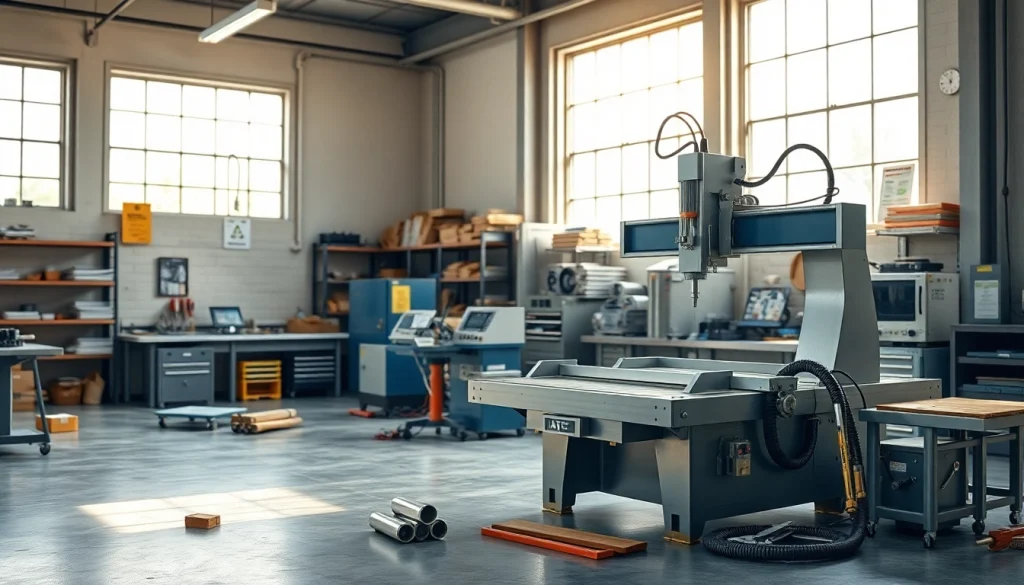

Cutting equipment plays a pivotal role in various industries, providing the tools necessary for precision and efficiency in manufacturing and construction processes. Whether you’re in woodworking, metal fabrication, or textiles, a diverse array of cutting tools is available to meet your specific needs. This article will explore the types, applications, and features of cutting equipment, enabling you to make informed decisions that enhance your operations. For those looking to optimize their workshop capabilities, understanding cutting equipment is fundamental.

Types of Cutting Equipment Explained

There is a broad spectrum of cutting equipment available, each designed for specific tasks and materials. Here’s a breakdown of some of the most common types:

- Band Saws: Versatile tools suitable for cutting curves and angles in wood and metal.

- Laser Cutters: Employ high-powered lasers for precise cutting, ideal for both metal and plastic materials.

- Water Jet Cutters: Use high-pressure water jets to cut through abrasive materials, noted for their ability to maintain the integrity of the workpiece without thermal distortion.

- CNC Machines: Computer-controlled machines offering high levels of accuracy and repeatability, ideal for mass production and complex designs.

- Manual Cutting Tools: Such as knives, shears, and manual saws, used for simpler tasks and smaller scale operations.

Common Uses of Cutting Equipment in Different Industries

Each type of cutting equipment serves unique roles across various sectors:

- Construction: Tools like saws and laser cutters are used for framing, roofing, and general construction tasks.

- Manufacturing: CNC machines and industrial cutting tools facilitate the mass production of components.

- Textiles: Rotary cutters and shears are crucial for detailed fabric work in fashion and upholstery.

- Woodworking: Band saws and chisels assist in creating finished products from raw lumber.

- Automotive: Laser cutting is utilized for precision parts in engine and chassis production.

Key Features to Look for in Cutting Equipment

When selecting cutting equipment, several key features should be considered to ensure optimal performance:

- Material Compatibility: Ensure the equipment can handle the materials you will frequently work with.

- Precision: Look for tools that offer accurate and repeatable cuts.

- Cutting Speed: Faster cutting can enhance productivity, so consider equipment that delivers speed without compromising quality.

- Ease of Use: User-friendly controls and settings can dramatically affect operational efficiency.

- Maintenance Requirements: Some cutting equipment requires more frequent maintenance, impacting operational downtime.

Choosing the Right Cutting Equipment for Your Needs

Selecting the appropriate cutting equipment can be a daunting task, especially with the diverse options available. Here are some considerations to help streamline your choice.

Assessing Your Cutting Requirements

Begin with a clear understanding of your cutting needs. Identify the materials, thicknesses, and types of cuts required for your projects. This assessment will guide you toward the most suitable equipment. Consulting with experts or conducting thorough research can also illuminate the appropriate specifications.

Budgeting for Quality Cutting Equipment

Quality cutting equipment represents a significant investment. Set a budget that reflects both your immediate needs and long-term goals. Consider the cost of not only the equipment itself but also associated expenses such as maintenance, operational costs, and potential upgrades. Investing in high-quality machinery may save money in the long run by reducing maintenance and improving efficiency.

Comparative Analysis: Manual vs. Automated Cutting Equipment

The choice between manual and automated cutting equipment often comes down to the scale and type of work. Manual tools offer unmatched versatility and are often less expensive and easier to maintain. However, automated equipment can significantly increase production rates and precision. Balancing the advantages of each type with your specific project requirements will dictate the best choice for your operations.

Safety Practices When Using Cutting Equipment

Utilizing cutting equipment comes with inherent risks. Proper safety practices are critical to protecting operators and ensuring a safe workplace.

Essential Safety Gear for Cutting Equipment

Before operating any cutting equipment, it is imperative to wear appropriate safety gear. Essential items include:

- Protective Eyewear: Goggles or face shields safeguard against flying debris.

- Gloves: Cut-resistant gloves provide hand protection without sacrificing dexterity.

- Hearing Protection: Earplugs or earmuffs can protect against noise-induced hearing loss.

- Aprons: Industrial aprons help protect the body from materials and debris.

Common Safety Procedures and Protocols

Alongside gear, adhering to safety protocols can prevent accidents. Key safety practices include:

- Conduct regular safety training sessions to keep all employees informed about best practices.

- Ensure equipment is properly maintained and inspected before use.

- Implement emergency shut-off mechanisms for immediate action in the event of an accident.

- Maintain a clutter-free workspace to improve safety and efficiency.

How to Maintain a Safe Workspace with Cutting Equipment

A safe workspace encourages productive work and minimizes the risk of incidents. Regularly clean the area, organize tools, and ensure all equipment is in good working order. Proper lighting and ventilation are also essential to maintain a conducive work environment.

Maximizing Efficiency with Cutting Equipment

To get the most out of your cutting equipment, it is essential to understand how to maximize its efficiency. This can be influenced by setup, maintenance, and operational techniques.

Best Practices for Equipment Setup and Use

Your cutting equipment should be set up according to optimal configurations to ensure efficiency. This includes calibrating machines for specific materials and cuts, ensuring that setups are ergonomic, and always referring to the manufacturer’s guidelines for use.

Integrating Technology with Cutting Equipment

Today’s cutting equipment can be enhanced with technology, including software for design and machining processes. Automating basic tasks can free up valuable labor resources for more complex tasks, leading to increased productivity and output quality.

Performance Metrics for Cutting Equipment Efficiency

Tracking performance metrics such as cut speed, material waste, and downtime can provide insights into equipment efficiency. Regular assessment against these metrics helps identify areas for improvement, increasing productivity over time.

Future Trends in Cutting Equipment Technology

The cutting equipment field is constantly evolving, driven by technological advancements and market needs.

Emerging Innovations in Cutting Equipment

Recent innovations have introduced cutting tools that incorporate IoT technology, allowing for remote monitoring and real-time analytics. Automated systems are becoming more sophisticated, providing predictive maintenance alerts and efficiency tracking.

Impact of Automation on Cutting Equipment

Automation is reshaping the landscape of cutting equipment. With advancements in robotics and AI, industries are witnessing improved productivity and precision. The transition from manual to automated processes can significantly reduce lead times and enhance output quality.

Sustainability Trends in Cutting Equipment Manufacturing

One of the noteworthy trends in cutting equipment is the shift toward sustainability. Manufacturers are adopting eco-friendly materials and processes, emphasizing waste reduction and energy efficiency to appeal to environmentally conscious businesses.

FAQs About Cutting Equipment